Angebot anfordern

Envialor (Kunststoffhändler)

- Startseite

- Lieferanten

- Nordamerika

- Envalior

Envalior (ein Joint Venture zwischen DSM Engineering Materials und LANXESS High Performance Materials) ist weltweit führend in der Entwicklung von Hochleistungsmaterialien für verschiedene Branchen, darunter die Automobil-, Elektronik- und Medizinbranche. Mit über 80 Jahren Erfahrung sind DSM und LANXESS seit langem verlässliche Partner für ihre Kunden. Gemeinsam bieten sie nun als Envalior weiterhin innovative Lösungen an, die den Kunden helfen, ihre Ziele zu erreichen.

Das Produktportfolio von Envalior umfasst eine breite Palette von Materialien wie technische Kunststoffe, Hochtemperaturkunststoffe und thermoplastische Elastomere, die außergewöhnliche Eigenschaften wie hohe Festigkeit, Haltbarkeit, Hitzebeständigkeit und chemische Beständigkeit bieten. Envalior ist auch auf die Entwicklung nachhaltiger Materialien spezialisiert, die zur Verringerung der Umweltbelastung beitragen, darunter biobasierte und recycelte Kunststoffe. Mit einem starken Fokus auf Forschung und Entwicklung erweitert Envalior ständig die Grenzen der Materialwissenschaft und schafft neue Lösungen, die den sich entwickelnden Bedürfnissen seiner Kunden und des Marktes entsprechen.

|

|

|

|

|

|

Klicken Sie auf ein Material für weitere Informationen.

Akulon®-Nylon 6 & 66 verfügt über Typen, die für alle Verarbeitungstechniken geeignet sind, einschließlich Extrusion, Spritzgießen und Blasformen. Für Formteile bieten sie ein ausgezeichnetes Gleichgewicht zwischen einfacher Konstruktion und Verarbeitung mit hervorragenden mechanischen Eigenschaften über einen weiten Temperaturbereich und in verschiedenen Betriebsumgebungen.

Arnite® A Polyethylenterephthalat (PET) und Arnite* T Polybutylenterephthalat (PBT) eignen sich gut für eine breite Palette von Anwendungen in den Bereichen Automobil, Elektrik und Elektronik (E&E) sowie Konsumgüter. Eine breite Palette von Arnite* ist erhältlich, darunter unverstärkte, verstärkte und flammhemmende (FR) Typen.

Arnitel® ist ein thermoplastisches Elastomer (TPE) mit hoher Temperaturbeständigkeit, guter Verarbeitungsfähigkeit und hervorragendem elastischen Verhalten. Arnitel gehört zur TPE-Unterkategorie der thermoplastischen Copolyester (TPC).

ForTii®-Polyamide (PPAs) sind hochleistungsfähige semi-aromatische Polyphthalamide, die auf der einzigartigen „C4“-Diamintechnologie basieren und eine ausgezeichnete Dimensionsstabilität, Kompatibilität mit bleifreiem Reflow-Löten sowie höchste Steifigkeit und mechanische Festigkeit bei extremen Temperaturen bieten.

Stanyl® Nylon 46 sind die ersten Hochtemperaturpolyamide und die einzigen aliphatischen Polyamide in ihrer Klasse. Die Symmetrie der Struktur sorgt dafür, dass sich die Polymere auf verschiedene Weise in den Kristall einfügen, was zu hohen Kristallisierungsgeschwindigkeiten und hoher Kristallinität führt.

Xytron™ Polyphenylsulfid (PPSs) bieten extreme chemische Beständigkeit, Dimensionsstabilität, Flammwidrigkeit, hohe Steifigkeit bis zum Glasübergangspunkt (90 °C), eine Dauergebrauchstemperatur (CUT) von 240–260 °C und einen Schmelzpunkt von 280 °C.

Durethan®-Polyamide 6 & 66 technische Thermoplaste (ETPs) sind ETPs, die von weichen und zähen Sorten bis hin zu extrem festen und steifen Sorten reichen.

Pocan® technische Thermoplaste (ETPs) werden aus Polybutylenterephthalat (PBT) hergestellt und bieten eine hohe Hitzebeständigkeit, Festigkeit und Härte sowie hervorragende Gleiteigenschaften und hohe Abriebfestigkeit, gute chemische Beständigkeit, geringe Spannungsrissanfälligkeit und geringe Feuchtigkeitsaufnahme. Flammhemmende, elastomermodifizierte und lebensmittelzugelassene Typen sind ebenfalls erhältlich, ebenso wie Mischungen mit Acrylnitril-Styrol-Acrylat (ASA), Polyethylenterephthalat (PET) und Polycarbonat (PC).

Pocan® technische Thermoplaste (ETPs) werden aus Polybutylenterephthalat (PBT) hergestellt und bieten eine hohe Hitzebeständigkeit, Festigkeit und Härte sowie hervorragende Gleiteigenschaften und hohe Abriebfestigkeit, gute chemische Beständigkeit, geringe Spannungsrissanfälligkeit und geringe Feuchtigkeitsaufnahme. Flammhemmende, elastomermodifizierte und lebensmittelzugelassene Typen sind ebenfalls erhältlich, ebenso wie Mischungen mit Acrylnitril-Styrol-Acrylat (ASA), Polyethylenterephthalat (PET) und Polycarbonat (PC).

Pocan® technische Thermoplaste (ETPs) werden aus Polybutylenterephthalat (PBT) hergestellt und bieten eine hohe Hitzebeständigkeit, Festigkeit und Härte sowie hervorragende Gleiteigenschaften und hohe Abriebfestigkeit, gute chemische Beständigkeit, geringe Spannungsrissanfälligkeit und geringe Feuchtigkeitsaufnahme. Flammhemmende, elastomermodifizierte und lebensmittelzugelassene Typen sind ebenfalls erhältlich, ebenso wie Mischungen mit Acrylnitril-Styrol-Acrylat (ASA), Polyethylenterephthalat (PET) und Polycarbonat (PC).

Pocan® technische Thermoplaste (ETPs) werden aus Polybutylenterephthalat (PBT) hergestellt und bieten eine hohe Hitzebeständigkeit, Festigkeit und Härte sowie hervorragende Gleiteigenschaften und hohe Abriebfestigkeit, gute chemische Beständigkeit, geringe Spannungsrissanfälligkeit und geringe Feuchtigkeitsaufnahme. Flammhemmende, elastomermodifizierte und lebensmittelzugelassene Typen sind ebenfalls erhältlich, ebenso wie Mischungen mit Acrylnitril-Styrol-Acrylat (ASA), Polyethylenterephthalat (PET) und Polycarbonat (PC).

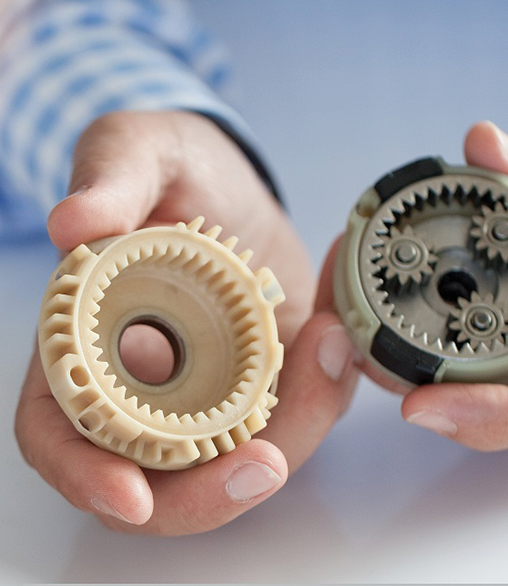

Nylatron® ist eine Marke für technische Kunststoffe auf Basis von Nylon 6/6, die für ihre außergewöhnliche Festigkeit, Haltbarkeit und selbstschmierenden Eigenschaften bekannt sind. Nylatron-Materialien werden häufig in Industrieanwendungen mit hohem P-V-Wert (Druck-Geschwindigkeit) eingesetzt und bieten eine hohe Verschleißfestigkeit und geringe Reibung, wodurch sie für Lager, Getriebe und andere mechanische Komponenten geeignet sind.

Klicken Sie auf ein Material für weitere Informationen.

EcoPaXX® biobasiertes Polyamid PA410 verfügt über die hohen mechanischen Eigenschaften typischer kurzkettiger Polyamide, kombiniert diese jedoch mit einer geringeren Feuchtigkeitsaufnahme und einer höheren chemischen Beständigkeit, die für langkettige Polyamide typisch ist.