Angebot anfordern

Monprene®-TPE

- Startseite

- Lieferantenprodukte

- Teknor Apex

- Monprene-TPE

Thermoplastische Elastomere (TPEs) sind aufgrund ihrer robusten Eigenschaften, ihrer Kosteneffizienz und ihrer Designoptionen die erste Wahl bei weichen, flexiblen Materialien. Als Weltmarktführer bei der Compoundierung bietet Teknor Apex eines der breitesten Portfolios von TPE-Technologien in der Branche, unter anderem Styrol-Block-Copolymer (SBC)-Compounds, Polyolefinmischungen (SBC oder TPE-S), thermoplastisches Vulkanisat (TPE-Vs oder TPVs) Polyurethan-Compounds (TPE-U oder TPU) und andere Spezialmischungen.

Von weichen Zahnbürstengriffen bis hin zu ergonomischen Griffen für Elektrowerkzeuge – Verbraucher erkennen den Komfort und die Sicherheit, die Monprene® TPE bietet. Diese vielfältige Produktlinie entstand aufgrund der Anforderungen des Marktes und umfasst mehrere TPE-Chemikalien, darunter SBC, TPV, TPO und TPU. Für eine schnelle Bemusterung stehen Standardtypen zur Verfügung, und Monprene® kann an spezifische ästhetische oder funktionale Anforderungen angepasst werden, was Designern, OEMs und Verarbeitern eine hohe Flexibilität bei der Gestaltung neuer Produkte bietet.

Teknor Apex verfolgt einen zielgerichteten Ansatz, um die Bedürfnisse der einzelnen Märkte zu erfüllen, und hat jede TPE-Produktreihe so entwickelt, dass sie den Anforderungen der jeweiligen Branche entspricht, die sie bedient. Standardmaterial entspricht häufig den geltenden Vorschriften und Spezifikationen für die jeweilige Branche. Daher sind die TPE-Compounds von Teknor Apex wahrscheinlich für Ihre Anwendung präqualifiziert, was die Markteinführung neuer Produkte beschleunigen kann. Zu den Merkmalen und Eigenschaften aller Monprene®-Produktreihen gehören:

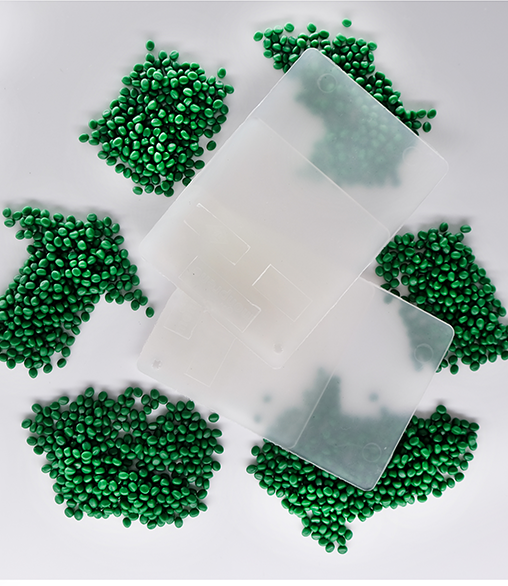

Neues umweltfreundliches Monprene® TPE in Zusammenarbeit mit UBQ™ Materialien.

UBQ™ ist ein nachhaltiger Kunststoffersatz, der vollständig aus organischen und nicht recycelbaren Abfällen hergestellt wird.

UBQ™ ist biobasiert und in hohem Maße recycelbar und bietet eine klimapositive Lösung für eine Kreislaufwirtschaft. Durch den Ersatz von ölbasierten Rohstoffen durch UBQ™ in TPE-Formulierungen trägt Teknor Apex dazu bei, die globale Abfallentsorgungskrise zu bewältigen, endliche natürliche Ressourcen zu schonen und die CO2-Bilanz Ihrer Endprodukte zu verbessern.

Der Monprene® S3 CP-15170 BLK-Typ, mit 70 Shore A und in schwarzer Farbe lässt sich vergleichbar gut verarbeiten wie erstklassiges TPE. Dies ist ein Material mit hohem Durchfluss, das speziell für das Spritzgießen oder das Umspritzen von Polypropylen entwickelt wurde. Dieses TPE eignet sich hervorragend für Anwendungen im Bereich der Konsumgüter, bei denen Flexibilität, Soft-Touch-Komponenten wie Anti-Rutsch- oder Komfortgriffe und verbesserte Ergonomie gefragt sind. Zu den üblichen Anwendungen gehören Hand- und Elektrowerkzeuge, Unterhaltungselektronik und Haushaltsgeräte.

Mit seiner positiven Wirkung auf das Klima und seinem wettbewerbsfähigen Preis ermöglicht UBQ™ den Herstellern einen einfachen Übergang zu höherer Nachhaltigkeit.

Merkmale und Vorteile

Von Anwendungen mit Lebensmittelkontakt und Haushaltswaren bis hin zu Unterhaltungselektronik, Haustierprodukten und Haushaltsgeräten – mit Monprene® können Sie Ihre Konsumgüter differenzieren. Monprene® thermoplastische Elastomere verleihen alltäglichen Konsumgütern Polsterung, Schutz oder einen weichen Griff. Monprene® kann so formuliert werden, dass verschiedene taktile Qualitäten erreicht werden, wie z. B. ein glattes, seidiges Gefühl oder eine klebrige Oberfläche für eine bessere Griffigkeit. Monprene® TPEs sind oft ideal für das 2-Shot- oder Insert-Molding und weisen eine ausgezeichnete Haftung auf starren Kunststoffsubstraten auf, was zu komfortableren Griffen, festeren Dichtungen und rutschfesten Oberflächen führt. Monprene® kann individuell eingefärbt werden, so dass es sich nahtlos in jede beliebige Farbpalette einfügt und die einzigartige Marke Ihres Produkts widerspiegelt. Typische Anwendungsgebiete sind:

|

|

|

Die Entwicklung innovativer Verpackungen, die strenge Leistungsanforderungen erfüllen und gleichzeitig den Zielen der Nachhaltigkeit und der Kosteneffizienz gerecht werden, ist einfach, wenn Sie das richtige Material für Ihre Anwendung haben. Von speziellen TPE-Mischungen, die in PE- und PP-Verschlüssen im Hotfill-Liner-Verfahren verwendet werden, bis hin zu Hochleistungs-TPEs mit überlegenen Sauerstoff- und Feuchtigkeitsbarriereeigenschaften, die in aseptisch abgefüllten Proteingetränkeanwendungen oder ROPP-Aluminiumverschlüssen zum Einsatz kommen, können TPEs von Teknor Apex die richtige Lösung bieten. Zu den gängigen Anwendungen gehören:

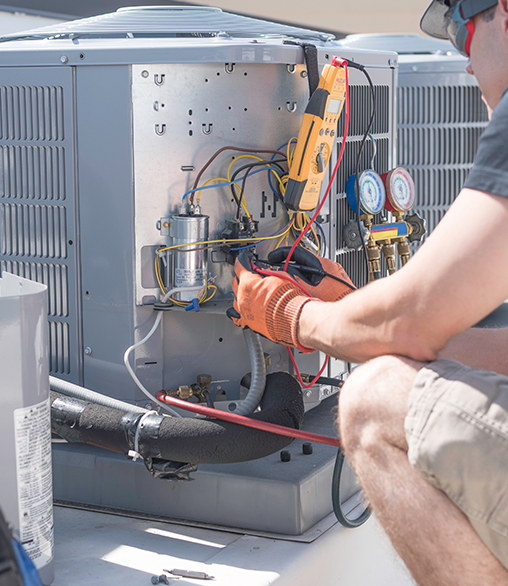

Monprene® TPEs werden aufgrund ihrer hervorragenden Leistung häufig für spezielle industrielle Anwendungen gewählt. Monprene® TPEs sind sehr elastisch und bleiben auch bei Minusgraden flexibel, was sie zu einer erstklassigen Option für Dichtungsanwendungen in Fluidmanagementsystemen macht, von automatischen Sprinklerdichtungen bis hin zu HLK-Dichtungen. Diese vielseitigen Materialien können mit einer Vielzahl von Eigenschaften, wie z. B. verbesserter Abriebfestigkeit oder UV-Beständigkeit, für unterschiedliche Endanwendungen angepasst werden. Monprene® TPEs können je nach Ihren Kosten- und Leistungsanforderungen gefüllt oder ungefüllt sein. Typische Anwendungsgebiete sind:

|

TPS CP-23060 NAT MONPRENE |

||

|

TPS CP-24038 XRD1 MONPRENE |

TPS PR-12241 NAT MONPRENE |

|

|

TPS OM-11260 NAT XRD1 MONPRENE |

||

|

TPS CP-19034 NAT MONPRENE |